The Art of Cigarette Rolling Paper Production

Cigarette rolling papers undergo a meticulous production process, encompassing raw material selection, precise processing, coating, and packaging. This article delves into the journey of cigarette rolling paper production, outlining each step from material selection to the final product. It aims to provide readers with insights into the fine craftsmanship and stringent quality control behind these papers.

Our brand, RollFun, specializes in crafting cigarette rolling papers using pure, natural materials. We employ 100% natural Arabic Gum, a classic and even-burning adhesive, to enhance your smoking experience.

-

Natural Material Selection: The foundation of high-quality rolling papers lies in selecting premium raw materials. At RollFun, we are committed to using pure and natural materials, ensuring the quality of our papers while being environmentally friendly. We meticulously select materials such as premium wood pulp, hemp fibers, or bamboo pulp that meet stringent standards to ensure exceptional texture, burn rate, and taste.

-

Pulping and Processing: The selected raw materials undergo a meticulous pulping process to ensure the paper's texture and strength. Our manufacturing process is precise and meticulous, resulting in rolling papers that exhibit excellent handling and reliable burning characteristics.

-

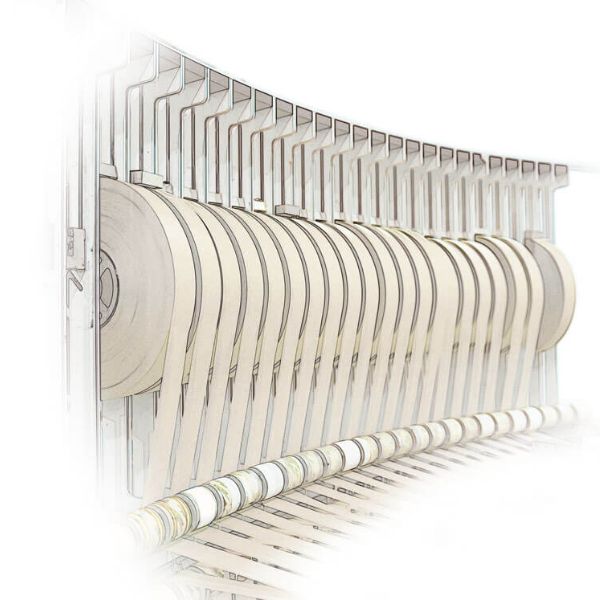

Paper Formation: Through meticulous processing, our RollFun rolling papers gradually take shape, resulting in uniform and stable sheets of paper. We employ specialized equipment to transform the pulp into thin sheets, which undergo proper pressing and drying to achieve optimal quality and consistency.

-

Coating and Enhancements: To enhance burn performance and smoking experience, our RollFun rolling papers are coated with the classic Arabic Gum. This 100% natural coating material helps seal the edges, making rolling easier and ensuring even and steady burn.

-

Quality Control: We maintain strict quality control measures for RollFun rolling papers. Throughout the production process, we have a team of skilled technicians who monitor the weight, thickness, burn rate, and other critical indicators of the papers. Each sheet undergoes meticulous inspection to ensure it meets our high standards, delivering an excellent smoking experience.

The production of cigarette rolling papers is an artful process, and RollFun is dedicated to crafting exceptional papers. We use pure, natural materials and employ 100% natural Arabic Gum to ensure the high quality and outstanding smoking experience of our rolling papers. By choosing RollFun, you can enjoy a classic and premium rolling paper that enhances your smoking pleasure.

Leave a comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.